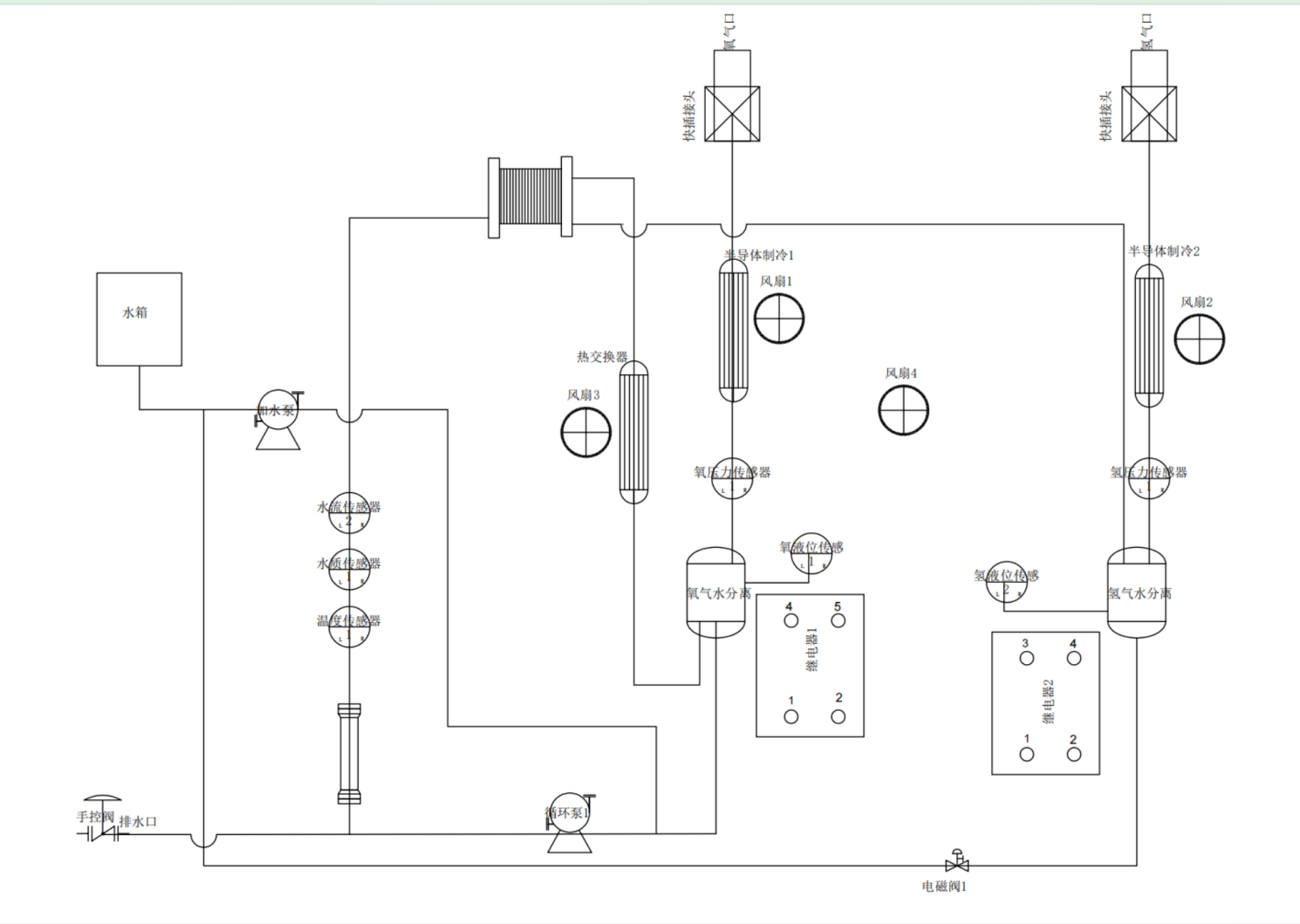

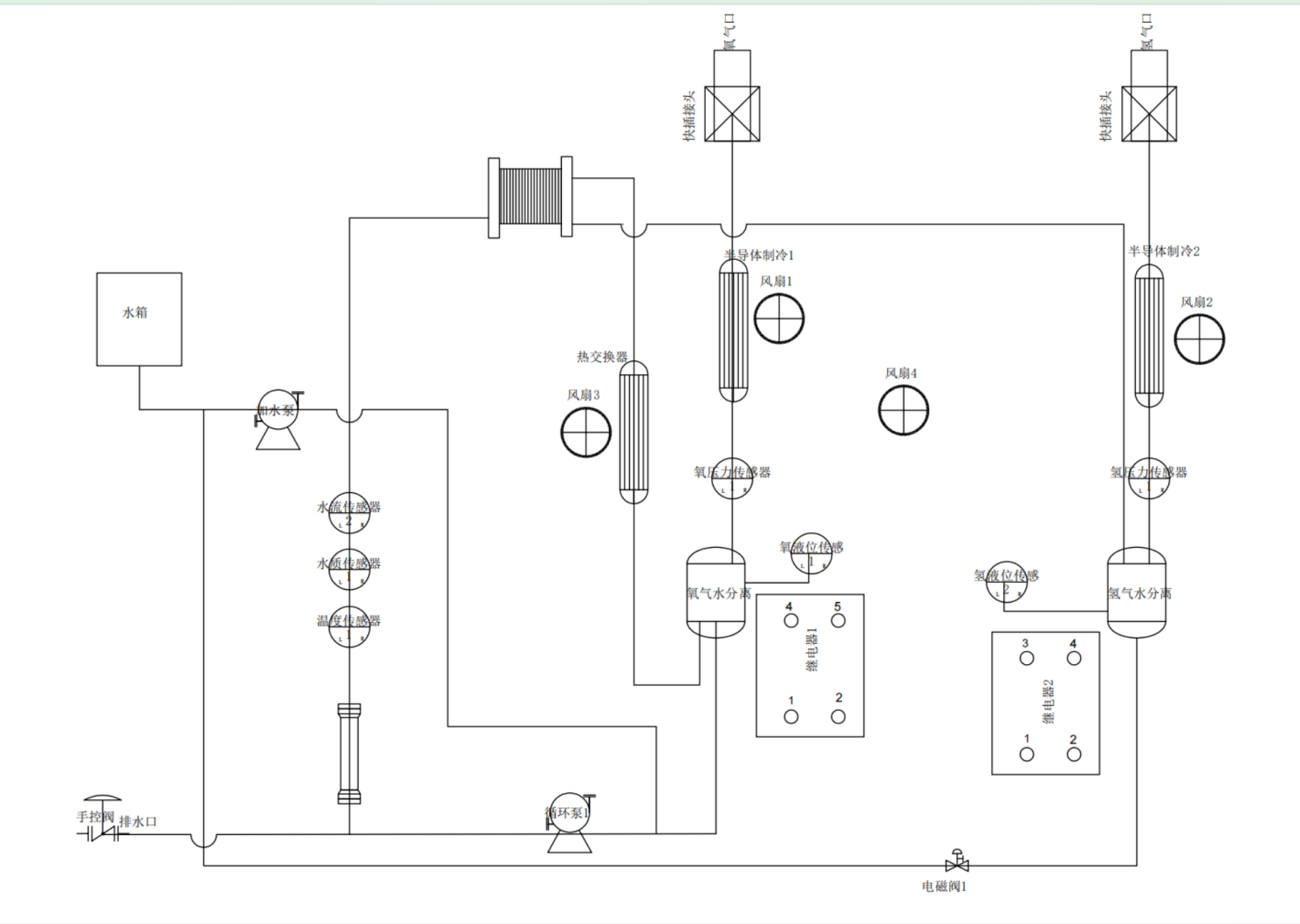

System Diagram

Complete water electrolysis system architecture

Professional Water Electrolysis System

2000ml-6000ml/min hydrogen output • 99.5% purity • Zero emissions

See the WOS-6000 in action with our product demonstration videos

Professional hydrogen generator with advanced control system

Intelligent touch screen interface with real-time monitoring

Advanced water splitting technology for hydrogen generation

Advanced water electrolysis technology for reliable hydrogen production

Generates hydrogen and oxygen through advanced water electrolysis. Requires high-purity water ≥10MΩ·cm for optimal performance.

6000ml/min hydrogen flow rate at standard configuration. Customizable power and output for different applications.

Delivers hydrogen with >99.5% purity through integrated ion exchange resin filtration and gas-water separation.

Integrated touch screen control panel with real-time monitoring, parameter adjustment, and safety management.

Advanced heat exchanger system maintains optimal operating temperature ≤60°C for reliable long-term operation.

Multiple safety features including pressure regulation (0-5MPa), temperature monitoring, and automatic shutdown protection.

WOS-6000 Standard Model (6000mL Configuration)

| Parameter | Specification |

|---|---|

| Rated Voltage | 220VDC : 50Hz |

| Rated Power | 2500W (Customizable) |

| Hydrogen Output Flow | 6000ml/min (Customizable:2000ml-6000ml) |

| Hydrogen Output Pressure | 0-5 MPa |

| Hydrogen Purity | >99.5% |

| Water Quality Required | ≥10MΩ·cm (High-purity deionized water) |

| Operating Temperature | ≤60°C |

| Ambient Temperature | 5-45°C |

| Relative Humidity | <85% |

| Environmental Conditions | No excessive dust or corrosive gases |

| Product Weight | 99 lbs (45 kg) |

| Product Dimensions | 23.6" × 14.2" × 22.2" (W × D × H) |

Professional engineering for reliable operation

Achieves gas-water separation before oxygen output, ensuring dry and pure oxygen delivery.

Removes moisture from hydrogen output stream, enhancing hydrogen purity and system reliability.

Core component where water undergoes electrochemical decomposition to generate hydrogen and oxygen through advanced electrolysis technology.

Purifies incoming water by removing impurity ions, ensuring water quality meets electrolysis requirements.

Dedicated outlets for hydrogen and oxygen discharge, connecting to downstream application or collection systems.

Integrated system for circulation pump control, hydrogen generation switching, and real-time parameter monitoring and adjustment.

Monitors and regulates circulating water temperature, maintaining optimal system operating conditions for stable performance.

Stores high-purity water supply for the electrolysis process with level monitoring and automatic control.

Complete water electrolysis system architecture

Versatile hydrogen generation for multiple industries

Clean hydrogen flames for precision welding applications

Fine metalwork and precious metal fabrication

Metal heat treatment and surface processing

Clean hydrogen supply for research applications

Production line hydrogen requirements

Glass forming and finishing operations

Precision medical equipment fabrication

Electronic component manufacturing and assembly

Professional advantages for demanding applications

Generate hydrogen as needed, eliminating storage risks and transportation costs associated with compressed gas cylinders.

Consistently delivers >99.5% pure hydrogen through integrated filtration and separation systems.

Lower operating costs compared to purchased hydrogen cylinders, with minimal maintenance requirements.

No high-pressure storage required. Built-in safety features include pressure control and temperature monitoring.

Robust industrial design with quality components ensures consistent operation in demanding environments.

Simple maintenance procedures with accessible components and clear service guidelines.

Trusted by professionals worldwide

"The WOS-6000 has transformed our manufacturing process. Reliable hydrogen supply without the hassle of cylinder management. Excellent investment for our facility."

"Outstanding purity and consistent output. The intelligent control system makes operation straightforward, and maintenance is minimal. Highly recommended."

"We've been using the WOS-6000 for over two years in our jewelry workshop. Clean, precise, and reliable - everything we need for fine metalwork."

Contact us for pricing and customization options